-

Introduction of Manufacturing Process

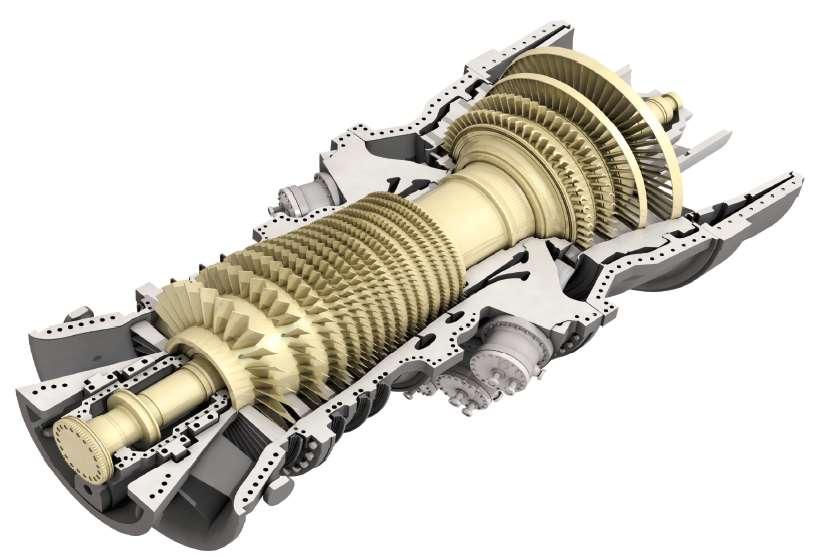

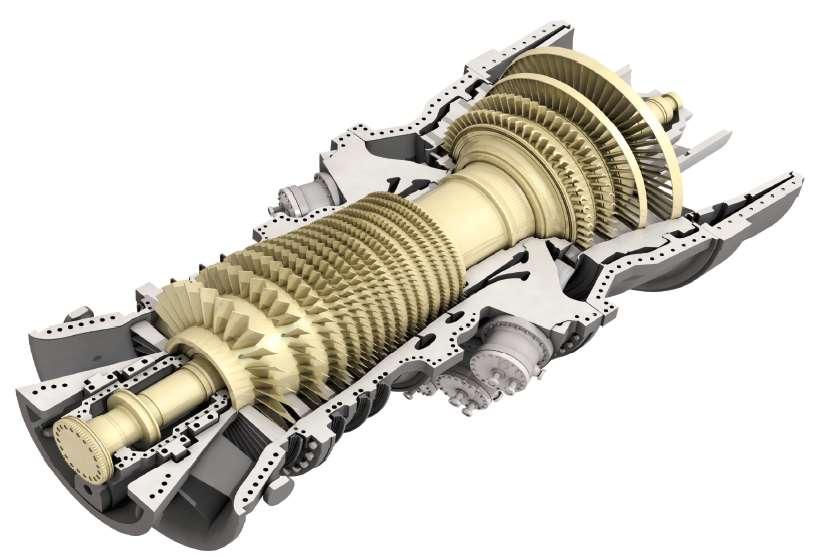

Gas turbines combust natural gas to generate high-temperature exhaust gas.

- 1External air is compressed by an air compressor to provide combustion air.

- 2In the combustor, air is mixed with fuel (natural gas) and ignited.

- 3The combustion gas rotates the turbine connected to the generator.

- 4Power is generated in the generator connected to the turbine.

- 5The gas turbine is rotated, and the exhaust gas that exits through the exhaust duct is sent to the heat recovery steam generator.

Gas TurbineFacility Specification Introduction- Anyang

- Bucheon

- Type

- 7HA.02

- Single

- 4 stages

- Outlet Temperature

- 631 ℃

- Type

- W501D5(Westinghouse)

- Single

- 4 stages

- Inlet Temperature

- 1118 ℃

- Outlet Temperature

- 530 ℃

Gas turbine & Compressor

CompressorFacility Specification Introduction- Anyang

- Bucheon

- Type

- Axial Flow

- Single

- 14 stages

- Compression Ratio

- 20.2

- Air Volume

- 685kg/s

- Type

- Axial Flow

- Single

- 19 stages

- Compression Ratio

- 14.1

- Air Volume

- 297kg/s

Gas turbine & Compressor

CombustorFacility Specification Introduction- Anyang

- Bucheon

- Type

- Can annular reverse flow

- Burners

- 12

- Fuel Volume

- 61.28ton/h

- Type

- Canannular

- Burners

- 14

- Fuel Volume

- 23ton/h

연소기

GeneratorFacility Specification Introduction- Anyang

- Bucheon

- Type

- 3-Phase 2-Pole Hydrogen Cooling Type

- Capacity

- 342MW

- Power Factor

- 0.9

- Frequency

- 60.0 Hz

- Voltage

- 25.0 kV

- Type

- 3-Phase 2-Pole Air Cooling Type

- Capacity

- 128MW

- Power Factor

- 0.9

- Frequency

- 60.0 Hz

- Voltage

- 13.8 kV

Generator

View Facility Specifications within the Process Go to the Process

-

Introduction of Manufacturing Process

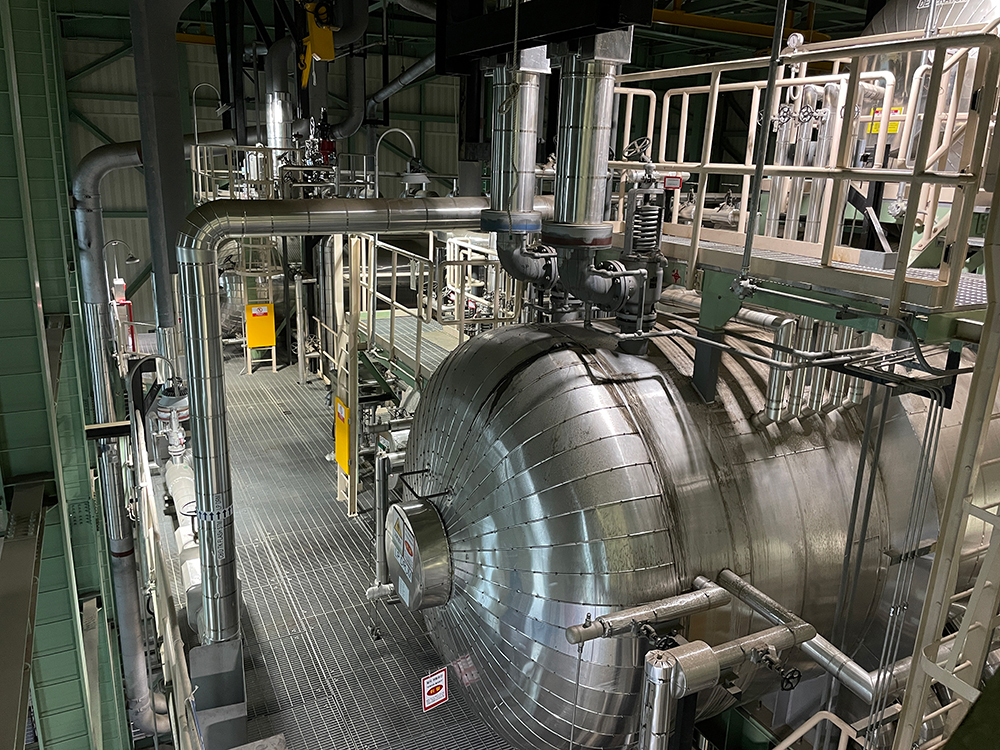

Heat recovery steam generator utilizes the heat from gas turbine exhaust gases to generate steam.

- 1The high-temperature exhaust gases discharged from the gas turbine are directed into the heat recovery steam generator.

- 2Heat recovery steam generator uses gas turbine exhaust gases to produce steam, which is then sent to either a steam turbine or a district heating water heater.

Heat Recovery Steam GeneratorFacility Specification Introduction- Anyang

- Bucheon

- Type

- Natural Circulation (Open Type)

- Steam Generation Capacity

- HP 308.6 ton/h, RH 343.1 ton/h, LP 36.5 ton/h

- Inlet Temperature

- 520 ℃

- Steam Temperature

- 600 ℃

- Pressure

- High Pressure: 148.73 kg/㎠, Mid Pressure: 30.03 kg/㎠, Low Pressure: 5.69 kg/㎠

- Type

- Forced Circulation Type

- Steam Generation Capacity

- HP 156.8 ton/h, LP 47.3 ton/h

- Inlet Temperature

- 530 ℃

- Steam Temperature

- 462℃

- Pressure

- High Pressure: 78.8 kg/㎠, Low Pressure: 6.0 kg/㎠

Generator

View Facility Specifications within the Process Go to the Process

-

Introduction of Manufacturing Process

It uses steam for both steam turbine power generation and heating.

- 1High-pressure steam is used to drive high-pressure turbines, and the resulting steam is sent to low-pressure turbines, with some of it going to the heating water heater.

- 2The low-pressure turbines drive and produce steam that is then condensed back into water in the condenser.

HP & LP TBNFacility Specification Introduction- Anyang

- Bucheon

- Type

- Reaction Turbine

- Single

- HP(24 Stages), IP (12 Stages), LP (5 Stages X 2)

- Steam Temperature

- HP 600℃, IP 600℃, LP 307.5℃

- Number of revolutions

- 3,600 rpm

- Type

- Reaction Turbine

- Single

- HP(17 Stages), LP (6 Stages)

- Steam Temperature

- HP 503℃, LP 158℃

- Number of revolutions

- 3,600 rpm

Steam Turbine

GeneratorFacility Specification Introduction- Anyang

- Bucheon

- Type

- 3-Phase 2-Pole Air-Cooled

- Capacity

- 170.1MW

- Power Factor

- 0.9

- Frequency

- 60.0 Hz

- Voltage

- 12.0 kV

- Type

- 3-Phase 2-Pole Hydrogen Cooling Type">

- Capacity

- 180MW

- Power Factor

- 0.9

- Frequency

- 60.0 Hz

- Voltage

- 18.0 kV

Generator

Heating Water HeaterFacility Specification Introduction- Anyang

- Bucheon

- Type

- Shell (Steam) / Tube (Water)

- Inlet Temperature

- 55℃

- Outlet Temperature

- 120℃

- Heat Output

- Mode Ⅰ (278 Gcal/h) Mode Ⅳ (360 Gcal/h)

- Type

- Shell (Steam) / Tube (Water)

- Inlet Temperature

- 65℃

- Outlet Temperature

- 120℃

- Heat Output

- Mode Ⅰ (357 Gcal/h) Mode Ⅳ (410 Gcal/h)

Heating Water Heater

Cooling TowerFacility Specification Introduction- Anyang

- Bucheon

- Type

- Wet - Dry

- Quantity

- 8 CELLS

- Capacity

- 23,170 ton/h

- Type

- Wet - Dry

- Quantity

- 10 CELLS

- Capacity

- 32,370 ton/h

Cooling Tower

View Facility Specifications within the Process Go to the Process

-

Introduction of Manufacturing Process

It is used to create heating water at 115°C through a heating water heater.

- 1The low-temperature heating water recovered after use in district heating is sent to the heating water heater.

- 2High-temperature steam is supplied from the steam turbine.

- 3High-temperature steam is supplied to the district heating water heater to heat the heating water.

- 4During the cold season and emergencies, the hot water boiler is operated to produce additional heating heat.

- 5Heat energy generated during the operation of the resource recovery facility is recovered and used as heating heat.

- 6The heating water produced in the heat production facility is supplied to consumers, and any excess heat is stored in the accumulation tank for later supply to district heating consumers as needed.

Water HeaterINTRODUCTION OF MANUFACTURING FACILITIESFacility Specification Introduction- Anyang

- Bucheon

Resource Recovery Facility(Incineration Heat)Facility Specification Introduction- Anyang

- Bucheon

- Anyang

- Heat production capacity 21 Gcal/hr

- Gunpo

- Heat production capacity 12 Gcal/hr

- Gwangmyeong

- Heat production capacity 23 Gcal/hr

- Gwacheon

- Heat production capacity 6 Gcal/hr

- Daejang-dong

- Heat Production Capacity per Installation 15Gcal/hr

BoilerFacility Specification Introduction- Anyang

- Bucheon

- Fuel

- LNG

- Type

- Water Pipe Type

- Capacity

- Heat production capacity 140Gcal/hr (1 Unit)

- Fuel

- LNG

- Type

- Water Pipe Type

- Capacity

- Heat production capacity 102Gcal/hr (1 Unit), 140Gcal/hr (1 Unit)

It is a facility that produces heat necessary for district heating supply and consists of a combustion device, ventilation device, water supply/fuel supply device, automatic control device, electrostatic precipitator, stack, etc. The steam produced in the boiler passes through a heat exchanger and is used as district heating hot water. It becomes warm.

AccumulatorFacility Specification Introduction- Anyang

- Capacity 20,000 ㎥ X 2

- Bucheon

- Capacity 25,000 ㎥ X 2

- 1This facility is used to temporarily store the heat required for district heating supply.

- 2It stores heat during periods of low demand and supplies it during periods of high demand.

- 3It also maintains the proper pressure in the district heating system.

- 4In case of a breakdown in the heat production facility, it can be used as an emergency heat source.

-

This is a facility that temporarily stores the heat needed for district heating supply. It stores the heat during times of low heat demand and supplies it during times of high heat demand, thereby maintaining flexible operation of the heat production facility and maintaining appropriate pressure throughout the district heating heat pipes. It is also used as an emergency heat source when heat production equipment malfunctions.

Accumulation_Save heat during times of low demand

Release_Supply during times of high heat demand

PumpFacility Specification IntroductionSupply Pump : Operating for smooth heat supply during the winter season.- Anyang

- 5Units 3,000 ㎥/hr X 2, 4,500㎥/hr X 3

- Bucheon

- 6 Units 3,400 ㎥/hr X 3, 2,300 ㎥/hr X 3

Recovery Pump : Operating during the production of heating heat in the heat production facilities (1st and 2nd stage heating water heaters, hot water/heat-dedicated boilers).- Anyang

- 5 Units 3,000㎥/hr X 4, 4,500㎥/hr X 1

- Bucheon

- 11 Units 3,000㎥/hr X 5, 3,400㎥/hr X 2, 1,100㎥/hr X 2, 1,050㎥/hr X 2

Axial Heat Pump : Operating during heat release/accumulation in the heat storage tank.- Anyang

- 3 Units 1,000 ㎥/hr X 3

- Bucheon

- 3 Units 3,150 ㎥/hr X 3

-

Axial Heat Pump : Operating during heat release/accumulation in the heat storage tank.

- Anyang

- 3 Units 1,000 ㎥/hr X 3

- Bucheon

- 3 Units 3,150 ㎥/hr X 3

View Facility Specifications within the Process Go to the Process

-

Introduction of Manufacturing Process

It supplies hot water from the user's mechanical room to each household or office.

- 1The supplied hot water, ranging from 90°C to 115°C, is used to heat the water that will be supplied from the mechanical room to each household or office.

- 2The cooled heating water is sent back to the heating water heating facility.

- 3Each user facility (apartment complex) is equipped with separate heating and hot water supply systems.

- 4Hot water is supplied by heating the tap water of the user facility (apartment complex).

Plate Heat ExchangerFacility Specification Introduction- "90°C to 115°C heating water supplied by GS Power is used to heat the heating water of the user facility through plate-type heat exchangers using conductive heat.

View Facility Specifications within the Process Go to the Process

-

Mode Ⅰ

Operation The representative operating method of combined heat and power generation is to generate electricity using a gas turbine and a high-pressure steam turbine, and to produce heating heat with the steam generated from the high-pressure steam turbine.

Gas Turbine + Heat Recovery Steam Generator + High-Pressure Steam Turbine + High and Low-Pressure Heat ExchangersMode ⅡOperation Operation method to operate gas turbine alone to produce electricity

Gas Turbine Single Cycle Operation (Single Cycle)Mode ⅢOperation Operation method to maximize electricity production using gas turbines and steam turbines (summer season)

Gas Turbine + Heat Recovery Steam Generator + High-Pressure Steam Turbine + Low-Pressure Steam TurbineMode Ⅳ4A ModeOperation Operation method that produces electricity with a gas turbine and generates heating energy with steam from the heat recovery steam generatorr (maximum heat production operation)

Gas Turbine + Heat Recovery Steam Generator + High and Low-Pressure Steam Heat Exchanger

4B ModeOperation Operation method that produces electricity with a gas turbine and condenses the steam generated from the heat recovery steam generator in the condenser, sending heat to the cooling tower.

Gas Turbine + Heat Recovery Steam Generator + CondenserMode ⅤOperation Operation method that combines Mode Ⅰ and Mode Ⅲ

Gas Turbine + Heat Recovery Steam Generator + High Pressure Steam Turbine + Low Pressure Steam Turbine + High and Low-Pressure Steam Heat ExchangerView description of each mode